About us

About us

Net Zero waste is committed to closing the loop on the food cycle. We utilize the organic waste produced in households

and commercial operations and transform this nutrient rich material into supercharged soil for use in your garden.

We provide the services necessary to support programs which promote and encourage both producer responsibility and user responsibility practices, particularly with regards to organic management. Our innovative design reduces the waste load on landfills extending their life span. Our facilities earn carbon credits as we avoid the production of methane in landfills which is a potent green house gas lowering the carbon foot print of the entire community.

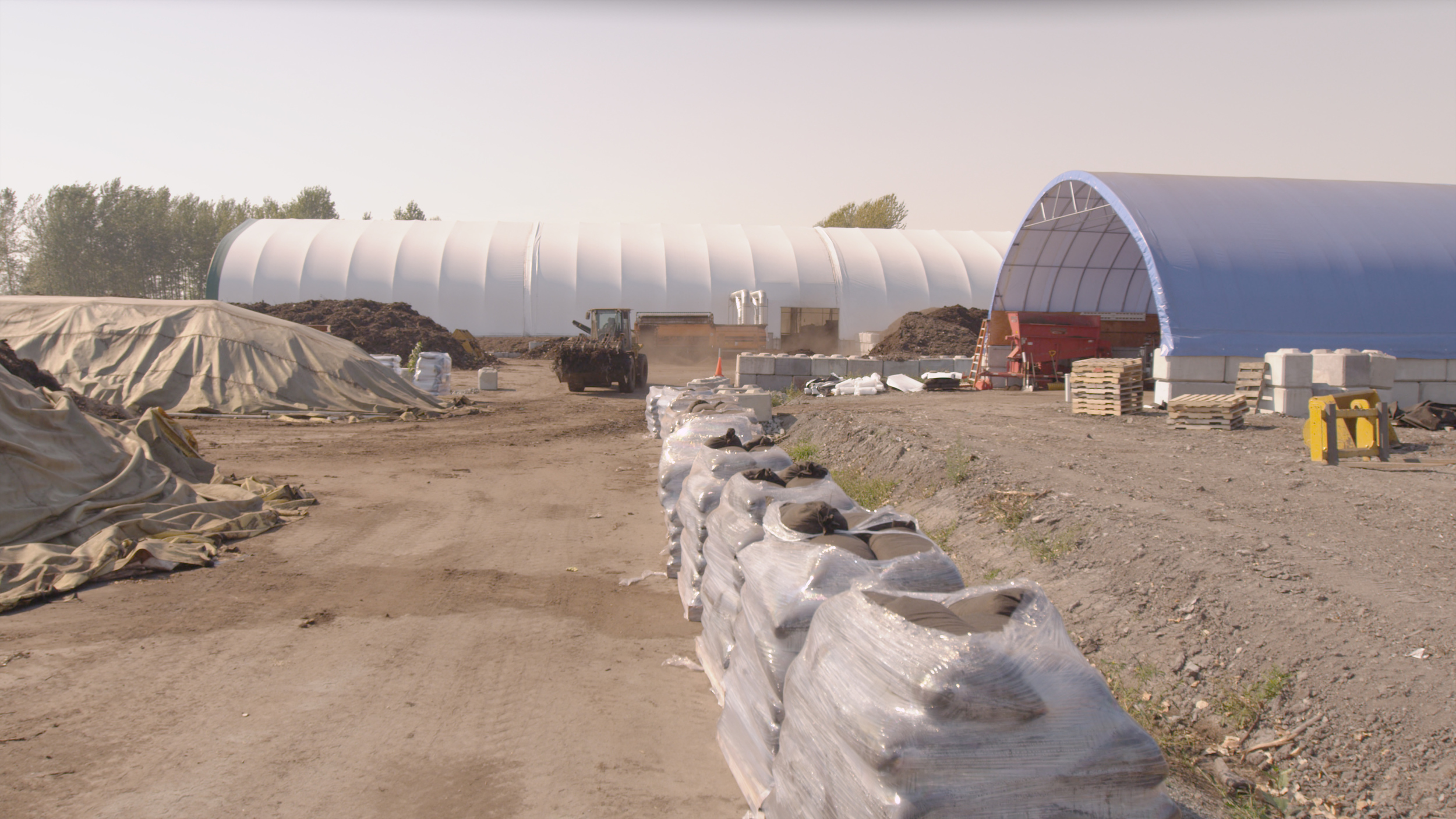

Gore Cover System

Gore Cover System

How it works?

The Gore Cover Traps Odors and moisture ensuring a 97% odor reduction from conventional windrow while providing the ideal environment for microbial activity.

The simple design of the Gore Cover System allows operations to proceed outdoors and in full view. Escalating maintenance costs associated with complex mechanical systems used in other technologies are also avoided.

Gore Cover System Features:

- Repels water

- GORE-TEX® membrane Industrial grade tarp

- Contains odors& humidity

- Allows CO2 pass through

- Retains heat

- Optimizes biological activity

Technology:

The Gore Cover System is classified as an in-vessel composting system by regulatory authorities and provides the following benefits over comparable technologies:

- Operations: Optimized operations and a reduction of stage treatment and multiple handling requirements (each heap is moved only twice)

- Utilities: Positive aeration drastically reduces utility operational costs (less than 1kWh of electricity per tonne of compost). The Gore Cover 2Hp blowers are on for approximately 2 minutes every 10. In comparison, “Negative Aeration Systems” must have their blowers on 24 hours a day 7 days a week to prevent negative odour events

- Layout: Compact design results in a drastically reduced facility footprint and a 400% improvement in throughput from conventional windrow systems

- Safety: Micro-porous GORE-TEX® membrane results in a microbe reduction of more than 99%

- Capital Cost: Very Competitive Project Start-Up Capital & Cycle Operation Costs allow the Gore Cover System to provide organic disposal fees well below landfill waste tip fees.

- Design Ingenuity: This Gore Cover allows a standard “Aerated Static Pile” to become an in-vessel system through the use of the patented membrane cover (This removes regulatory requirements for an enclosed facility)

Technology

Technology

Our Strategy

Net Zero Waste has focused its operational strategy around the Gore Cover System which is based on a membrane laminate technology similar to that of the Gore-Tex fabrics used for outerwear and footwear. Installed in more than 150 plants in 26 countries world wide, the benefits of the Gore Cover System include odor reduction of 90-97%; Bio-aerosol Emissions reduction of greater than 99 percent; less than 1 KWH/ton Energy Requirement and a three square feet/ton space requirement.

PROVEN RESULTS

The Gore Cover System results in more than a 97% reduction in odour concentrations without the need for bio-filters or expensive facility exhaust fans.

Due to the optimized biological process under the Gore Cover, accelerated High Rate Composting occurs resulting in much higher facility throughput. (400% higher than conventional windrow or up to 9 Tonne/m2 per year)

Experience

Experience

METRO VANCOUVER GORE COVER PROJECT

This trial project was designed to simulate the operation and performance of a full scale Gore Cover Composting Facility treating a 50% food waste mixture. Approximately 260,000 lbs of waste was composted by the process producing a stable high quality compost after only two months. Odour sampling was conducted during the trial demonstrating more than a 95% reduction in ammonia and VOC's.

Following the trial, Metro Vancouver issued a report recommending the sole sourcing of the Gore Cover System as the lowest risk technology worldwide (see pdf. file attached). The Metro board elected not to follow the recommendation of staff and undergo a competitive bid process with 21 competing firms. Net Zero Waste was selected as the preferred proponent for the eastern region, and a 60,000 TPA contract however Metro Vancouver elected not to move forward with our site as we were located on ALR lands. Our 10 acres of unused farm land, sits vacant today and the 50 acres of greenhouses surrounding these lands (previously used to grow tree seedlings) remains unutilized. Our proposal would have captured heat from the compost process to sustain a vibrant greenhouse business on this site.

CHEMAINUS BIO-SOLIDS GORE COVER PROJECT

Initially started as a trial, a series of batches were tested with various wood waste products until the correct mixture was determined. Modifications to the mixing of the pile and the best operational practices were also made during the processing of the demonstration batches.

Following the trial, Coast Environmental and NZW constructed a small indoor 8,000 tpa facility with small covers and a single aeration trench. A small scale winder was developed to be used in combination with the loader to place and remove the covers.

SEA TO SKY SOILS INC. COMPOST FACILITY DEVELOPMENT

Net Zero Waste partnered with a local operator to establish and permit a successful compost facility which now processes commercial food waste from Whistler and will begin to process curbside SSO from Squamish in the spring of 2015. This operation includes the production of micro-greens and at the source collection from select local producers. Restaurants love the concept of utilizing delicious locally grown micro-greens made in part from their own food waste, for “cradle to cradle” recycling and the highest end use possible of nutrient rich food waste in the region. (Visit website)

SALISH SOILS – FISH WASTE COMPOSTING FACILITY, SECHELT, BC

Developed in partnership with the Sechelt Nation, NZW trained staff; developed feedstock mixes and provided project engineering and support for project start-up and expansion. A design which places the gore cover system inside of a building allows the facility to be located close to town without negative environmental impacts. This project is processing high concentration fish waste mixtures so as to develop a boutique nutrient rich soil amendment for bagged distribution [$2 million, 09/2010 - Present]

(Read MORE ENVIRONMENTAL EXPERIENCE)

Projects

Projects

COMOX VALLEY REGIONAL DISTRICT WASTE PILOT OPERATION

This food waste pilot project commenced in May of 2013 with the participation of the Village of Cumberland and the Town of Comox and was the culmination of efforts made by staff to get a program off the ground in the short term. It is expected that the program will be expanded upon in the years ahead as other communities in the area are eager to commence organic recycling given the successful implementation and lack of contamination seen in the role out of this new program. Costing the regional district less than $65/tonne to process a relatively small amount of tonnage is allowing them to save money on solid waste disposal, while consensus is reached in neighboring communities on where best to site a facility. It will be difficult for other processors to compete on a price per tonne basis given the low population of the region and the relatively small amounts of available organics for full scale recycling. Select schools are expected to begin participation in the program in the fall which will aid in community education and expansion of the program.

CITY OF ABBOTSFORD FOOD WASTE PROCESSING FACILITY

Net Zero Waste Inc. was recently successful in its bid to design build, own and operate a food, green and agricultural waste commercial composting facility for the City of Abbotsford. This facility will be responsible for the treatment of organic waste for Abbotsford’s approximately 150,000 residents and provide a vital processing option for other commercial and agricultural wastes produced in the Fraser Valley. Our facility design will utilize an in-vessel design by placing the standard Gore Cover Processing Model inside of a building with secondary biofilter control. Furthermore, through the use of waste heat energy recovery, this site will utilize the high temperatures experienced below our compost piles to provide heat to greenhouses or other indoor agricultural initiatives, further improving the sustainability of the entire operation. Agricultural initiatives already underway by the landowner have always been the primary component of the site operation with hog barns redeveloped to indoor farming and vermicomposting operations. Our compost operation provides a significant opportunity for waste heat recovery, further improving the sustainability of all initiatives while encouraging the construction of greenhouses.

SEA TO SKY SOILS GORE® COVER COMPOSTING FACILITY

Sea to Sky Soils was founded by Net Zero Waste in 2011 at a site just North of Whistler BC. SSS processes the regions food waste sustainably and without a single odour complaint since 2012. The site is located on land owned by the Mount Currie Development Corporation and the operation utilizes band members for many of the staff positions on site. With a capacity of 50,000 wet tonnes annually and a staff of 8 – 10, our facility makes a positive influence on the local community. This facility also grows micro / baby greens to many of the high-end restaurants in the community as well as at all local grocery stores.

Team

Team

Mateo Ocejo

Director

Prior to founding Net Zero Waste Inc., Mateo Ocejo spent 10 years working in the environmental industry, most recently with AECOM (formerly known as Earth Tech Canada). During that time, Mateo has provided a wide range of private and public sector clients with guidance and support in the design and implementation of cost effective environmentally sustainable and publicly accepted diversion strategies.

A specific focus has been placed on the Gore Cover Technology, which is relatively new to North America, as Mr. Ocejo has been recognized as an expert in the design and construction of this process technology. Over the past 15 years, Mr. Ocejo has focused his efforts on developments in the solid waste industry; specifically, as they relate to composting. Mr. Ocejo is a professional engineer in good standing with the Province of BC, and has successfully acted as a qualified professional for compost facility permitting (OMRR) at multiple site locations within BC. Mr. Ocejo is the Technical Director on the board of directors for the Compost Council of Canada.